A cement chipboard is a composite sheet material made from a mixture of wood chips with cement. Thanks to this, partly contradictory combination, the TsSP slab received valuable characteristics and is widely used in construction.

How to make a DSP

The cement-particle mixture from which the DSP is made is a kind of concrete based on a mineral binder. Only instead of sand and gravel the filler in it is small wood shavings. The introduction of wood into the composition of the slab reduced its density, but most importantly, the shavings played the role of not only a light filler, but also fiber - an additive that creates volume reinforcement that can absorb tensile loads.

The mixture for the manufacture of plates includes:

- cement - 65%;

- shavings - 24%;

- water - 8.5-9%;

- mineralizing and hydration additives — 2–2.5%.

The preparation of the mixture begins with grinding the chips to the desired size. After that, it is divided into sieves into two fractions. The shallow one is used to form the outer layers of the sheet, the larger one is used for the middle layer. Then it is treated with calcium chloride, "liquid glass", chloride or aluminum sulfate. This is necessary to protect the material from decay and fungus infection.

The chips sifted and treated with mineral additives are mixed with water and cement. Additives that accelerate the hardening of cement dissolve in water. In addition to these components, fuel oil and I-20 industrial oil can be added to the mixture in small quantities to reduce internal friction and facilitate pressing.

The prepared mixture is laid out in three layers on pallets, the pallets are collected in a stack and placed in a cold press, where this “packet” is compressed to a pressure of 1.8-6.6 MPa and locked in this state by locks. A special lock system retains pressure in the mold after removing it from the press.

Compressed bags are heated for 8 hours. During this time, accelerated hydration of cement and its hardening occur. Due to its elasticity, wood shavings compensate for the shrinkage of cement, therefore, the specified dimensions of the plates do not change. Unlocking molds and relieving pressure also occurs in the press. After this, the package is opened, and the plates are removed and placed for 1-2 weeks in a buffer warehouse.

For the final ripening of the material, it is blown with air with a temperature of 70-100aboutC. After this, the sheets are cut to size, polished, sorted and transferred to the finished goods warehouse.

Varieties of DSPs and their sizes

According to GOST 26816-2016, cement-bonded particleboards of two grades are produced - TsSP-1 and TsSP-2. They are distinguished by dimensional accuracy, durability and other quality parameters.

| Options | TsSP-1 | TsSP-2 |

|---|---|---|

| Slab deviations (mm) | 3,0 | 5,0 |

| Deviation in thickness of unpolished boards (mm) | 0,7-1,5 | 0,8-0,16 |

| Bending Strength (MPa) | 9,0-12,0 | 7,0-9,0 |

| Delamination Strength (MPa) | 0,50 | 0,35 |

| The roughness of polished boards (microns) | 80 | 100 |

| Surface stains | Not allowed | Not allowed more than 1 pc. di ameter more than 20 mm per 1 m2. |

| Dents | Not allowed more than 1 pc, with a depth of more than 1 mm, a diameter of more than 10 mm per 1 m2. | Not allowed more than 3 pcs. more than 2 mm deep, with a diameter of more than 20 mm per 1 m2. |

The limits of variation in thickness and bending strength are set separately for different thickness ranges. Plates are made from 8 to 40 mm thick with a gradation of 2 mm.

The sizes of sheets of DSP of both brands are the same:

- Length - 3200 or 3600 mm;

- Width - 1200 or 1250 mm.

In addition to these two grades, there are “related” materials with similar composition and properties.

Fiberboard

These are boards filled with wood fibers, the so-called wood wool.A filler of this form provides better fibration, which positively affects the strength of the material and its resistance to cracking. The fiberboard is relatively soft, has a relatively low density and is often used for thermal insulation and as a sound absorber.

Arbolite

Material related to lightweight concrete. As a filler, it uses wood chips, wood chips, chopped reed stalks and rice straw. Arbolite has a low strength and is used in structures that do not carry loads, for example, internal partitions.

Xylolite

This material is made using a magnesia binder - Sorel cement. Insensitive to water. It is used for cladding floors, roofs and other structures where frequent wetting of plates is possible.

DSP Characteristics

The main characteristics of a DSP are determined by its constituent components. For example, the severity of the cement stone is partially offset by the lightness of the filler - chips.

Physico-mechanical properties of DSP according to GOST 26816-2016:

| Index | TsSP-1 | TsSP-2 |

|---|---|---|

| Flexural modulus, MPa | 4500 | 4000 |

| Hardness, MPa | 45 - 65 | |

| Thermal conductivity, VT / (m0FROM) | 0,26 | |

| Specific heat, kJ / (kg0FROM) | 1,15 | |

| Specific Resistance to Pulling Screws from the Plast, N / m | 4 - 7 | |

| Biological resistance class | 4 | |

| Frost resistance: | ||

| - the number of cycles of variable freezing / thawing without visible signs of destruction | 50 | |

| - residual strength,% | 90 | |

| Resistance to cyclic temperature and humidity changes: | ||

| - reduction in strength after 20 cycles of temperature and humidity,% | 30 | |

| thickness swelling, field of 20 cycles of temperature and humidity effects,% | 5 | |

Density and weight of the plate

The density of the DSP is 1100-400 kg / m3 - This is less than the density of most cement-based materials. A slab measuring 3200 × 1200 × 10 mm weighs from 42 to 54 kg, depending on the density.

Moisture and Biostability

DSP is resistant to moisture and biological factors. Biostability is provided by special processing of chips - mineralization. Moisture resistance is a merit of cement. Cement stone does not lose strength with any moisture. Water absorption during prolonged immersion in water does not exceed 16%, and the swelling of the plate in thickness fits into 1.5%.

Frost resistance

When moistened, the DSP absorbs water a little. This determines its good resistance to low temperatures. Frost resistance of TsSP - 50 cycles of freezing-heating without visible damage and at 90% residual strength. According to this parameter, the boards are suitable for use outside heated rooms, provided that they are protected against moisture accumulation.

Thermal conductivity and vapor permeability

Cement bonded particleboard is a porous material, since a significant part of the volume in it is wood shavings. Due to this structure, it has a low thermal conductivity - about 0.26 W / (m ∙ ° С). This is 1.5-2 times less than that of a brick and about twice as much as that of a drywall. Despite the fact that DSP cannot be fully considered a heat-insulating material, its use significantly affects the resulting thermal resistance of external building envelopes.

The porous structure determines the permeability of the material for water vapor at the level of 0.03 mg / (m ∙ h ∙ Pa). Concrete has the same vapor permeability. This parameter must be taken into account when designing multilayer walls. When using a DSP slab for interior decoration of external walls, it can serve as a vapor-limiting layer that reduces the accumulation of moisture in the wall and increases the efficiency of thermal insulation.

Fire safety

The fire characteristics of the DSP are as follows:

- combustibility group: G1: hardly combustible;

- flammability group: B1 - hardly flammable;

- flame spread: RP1 - non-flame propagating;

- smoke formation: D1 - a small amount of smoke;

- toxicity group: T1 - combustion products are low toxic.

By the sum of the parameters, a cement-bonded particleboard is classified as safe material.Its use allows to increase the fire resistance of building structures and reduce the fire hazard class of premises.

Environmental friendliness

This characteristic is given a lot of attention in connection with the massive use of synthetic raw materials in the production of building materials. Cement bonded particleboard consists only of natural components. It does not contain formaldehyde resins, polystyrene and other substances that can serve as sources of emission of volatile toxic compounds. Thanks to mineralizing additives, the wood component is not susceptible to decay, which also contributes to maintaining a healthy atmosphere in the premises.

Treatment

Cement-bonded particleboard is quite easy to cut and drill, which greatly simplifies the work with it. Putties are well placed on its surface, it is well painted.

DSP application

The scope of the cement-bonded particleboard is determined by its properties described above. Especially valuable is a successful combination of valuable qualities that complement each other. Not many materials have strength, moisture resistance, environmental friendliness, fire safety and relatively low weight at the same time.

The shape of the material in the form of plates gives another important advantage - ease of use, manufacturability. The use of DSP in many cases allows you to speed up the work, to exclude the so-called “wet processes”, which require special skills from the masters, are time-consuming and time consuming, especially considering the curing time of building mixtures.

The use of cement-bonded particleboards is reduced to installation work, the large dimensions of the sheets allow you to immediately cover a large area and simplify the alignment of planes.

Sheathing of walls and partitions

Cement-bonded particleboards are very well suited for wall cladding, both massive and frame. Environmental safety makes them a good material for interior decoration, and moisture resistance allows it to be used for wet rooms and for exterior decoration of buildings.

Slabs can be mounted on brick walls instead of conventional plaster. This method is called “dry plaster”. Facing with slabs makes it easy to get a flat surface. The complexity of this work, given the simplicity of ensuring the proper quality, is much lower than with traditional plastering. For these purposes, sheets of thickness 8-12 mm are usually used.

Cement chipboards are very well suited for frame construction. This technology directly provides for sheet sheathing, which ensures high technological work and time saving. One of the types of frame structures is internal partitions. DSPs serve as sound-insulating material that reduces the acoustic connection between rooms separated by a partition. For sheathing frames use plates up to 20 mm thick.

Hinged facade systems

The hinged ventilated facade is one of the natural applications of DSP. These sheets serve as external cladding that protects the inner layers from atmospheric moisture and wind. Strength, moisture resistance and fire safety of the material are extremely important for a ventilated facade. DSP is able to withstand high mechanical loads, does not deteriorate from moisture and does not spread flame, even in conditions of strong traction in the ventilation gap. Lightweight plates up to 12 mm thick are used in this area.

Roofing systems

DSP is used in the construction of flat roofs, including exploited ones. Sheets are laid on top of the insulation and then covered with a waterproofing membrane. Due to the rigidity of the plates, the insulation is not exposed to concentrated loads and you can walk on the roof, and even use it, for example, under a summer cafe or relaxation area. Depending on the load, roofing systems use plates up to 20 mm thick, and in special cases more.

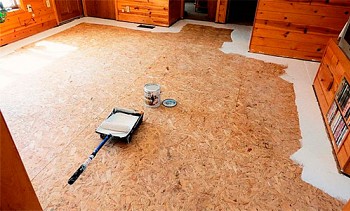

Floors

For the device of the floor, such properties of the DSP are useful as bending strength and moisture resistance. This material is very suitable for the subfloor - the so-called dry screed.Instead of spreading a layer of cement-sand mixture on the ceiling, smoothing it and waiting until it hardens, the CSP slabs are laid on the prepared “beacons” and immediately a foundation is obtained that is even and ready for further finishing, and also serves as a heat insulator.

For a frame house or when installing the floor on logs, thicker plates are taken. The choice of thickness is determined by the upcoming load and the distance between the lags.

Another frequently used design is a floating floor. For her, DSP is also perfectly suitable, as well as for a flat insulated roof. The choice of plate thickness is influenced by the calculated loads and the density of the insulation. For a rough floor, boards with a thickness of at least 14 mm are used.

Formwork

Typically, in monolithic construction, formwork is a temporary structure that is removed after the initial hardening of concrete. Using DSP allows you to combine the preparation of formwork with finishing work. Permanent formwork is made from these plates, which remains as part of the wall, immediately forming a smooth surface that does not need plastering.

Garden paths

This is one of the possible applications of the DSP board. Here, its strength and moisture resistance come in handy. Laying slabs on the prepared sand "cushion" creates a flat surface that will not crumble, crack, on which there will be no dips or swelling. Of course, to compensate for frost heaving, you need to take care of the construction of a high-quality drainage layer.